PSK Group's commitment to high quality equipment

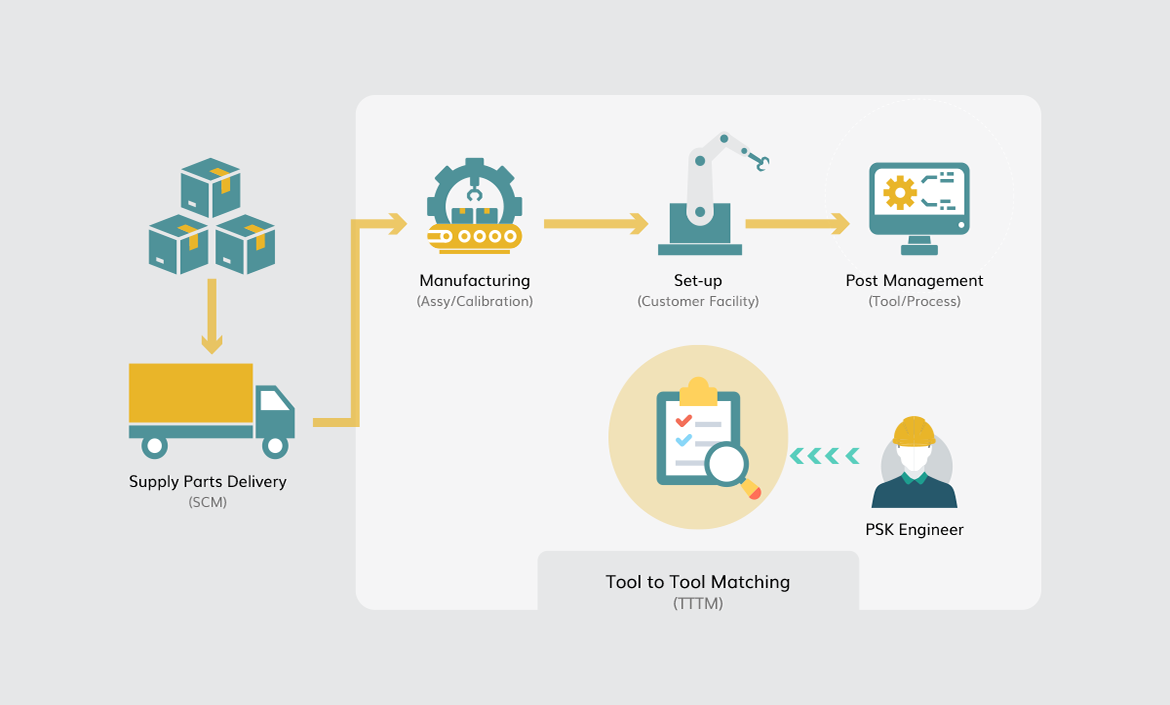

In order to improve productivity and quality control, PSK Group operates a management system covering every step of the process. When a problem occurs, it is handled according to this system by a customer support team of systematically managed professional engineers.

PSK Group collaborates with partners to optimize quality of parts and modules through CEO Mind, Man, Machine, Method, and Material management.

Manufacturing is managed according to locking, clamping, lubrication, driving, pneumatic, electric, control, and instrumentation categories.

Tool to Tool Matching(TTTM) increases PSK equipment accordance between manufacturing and set-up process through cooperation of responsible PSK engineers.

Parameter and data are collected through Smart EES after set-up, where a maintenance history of the equipment is managable and accessible anytime.

Tool to Tool Matching system (TTTM)

TTTM is deployed to ensure equipment produced by PSK performs same every time.

Maintenance management system

History of equipment setup by PSK Group is systematically managed to improve customer satisfaction.

PSK Group's engineer management

PSK Group's engineer is educated and trained to perform standardized process